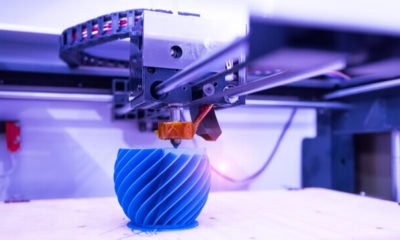

The technology that we have these days is constantly changing and growing. With new 3D printing capabilities more and more industries are figuring out how to put this technology to work. With something as convenient and useful as 3D printing, the automotive industry can certainly benefit from its use.

3D Printing and Mass Production

One way that 3D printing is changing the automotive industry is in terms of mass production. 3D printing is quick, it is efficient, and it opens a world of possibility in terms of getting parts made on-site when needed. In times past, it would take days to get your parts made, if they were even made in the US. The process of getting parts on-site when needed often took ordering, waiting for shipping, and then having to sift through what you have and make sure you are getting the part that you need. With 3D printing, it is possible to print the parts you need, on-site, and quickly. This means less waiting time, less downtime, and a product with the same result of the car being fixed and production moving right along.

When it comes to manufacturing cars it is often too expensive to order small batches of parts but using 3D printing can help to cut costs, can help to make low-volume customizations easier and can also help to get your parts to you faster so that you can start work and get more cars off the line.

Cost Reduction

In terms of reducing costs, 3D printing can also do a great deal to cut the costs of the parts that you need to get cars running. As mentioned before, 3D printing can nearly eliminate shipping costs when it comes to parts that were once needed to get products shipped to one place or other are reduced drastically when you put 3D printing into effect and into use. 3D printing makes the creation of necessary parts on-site possible which helps to reduce costs, reduce time, and make it possible to have the parts you need on hand quickly.

The initial cost of buying a 3D printer is what shocks a lot of people but after that cost is dramatically cut in terms of ordering parts and getting your parts to your shop or to the factory. 3D printing can help with cutting costs for parts like mounting brackets and new designs that may not be on the production floor already. A traditional production process can take weeks with the design being sent off and engineers having to wait for the final product to make its way back. 3D printing takes very little in the way of input, the engineers on-site can put in the information and have the product back by the next day for testing and use, this reduces cost, time, and overall effort as well.

Customization

Another fact that makes 3D printing beneficial is that it allows for customization on-site, something that was once very expensive and time-consuming. 3D printing allows measurements, designs, and shapes that may be costly in other forms of production to be used and for those parts to be created on-site and to be then put into use. 3D printers can also be used in the production of highly detailed prototypes which means that if companies or individual manufacturers are looking to create prototypes for designs, they wish to create and need to quickly visualize it.

3D printing opens a whole new world of possibilities when it comes to the creation of parts, the creation of custom parts, and the ability to get parts created on-site quickly and easily. 3D printing can create things like complex ducting, flexible bellows, and more. 3D printing is only limited by what engineers can create and by what is needed within the shop or the production floor.

3D printing is a fantastic thing, it can help those that need complex parts that may not exist to bring them to fruition. It can help cut costs on shipping parts and on getting them to the production floor quickly. It can also save time, effort, and overall hassle in terms of the automotive industry and in producing vehicles. 3D printing is going to keep improving, keep getting better, and keep getting easier and easier to use in the future.